BEEAH Recycling’s solution to deriving value from waste starts with a state-of-the-art Waste Management Centre.

Through a carefully planned phasing strategy, the company has built some of the world’s most advanced recycling facilities at this Centre.

These facilities maximize recovery and waste diversion, while driving the zero-waste agenda set by BEEAH Group. At these facilities, waste is sorted, processed, treated and regenerated in forms that further benefit the economy.

Material Recovery Facility (MRF)

The third largest facility of its kind in the world, and one of the largest producers of recyclables in the region, the Material Recovery Facility operates using state-of-the-art recovery technologies. The MRF uses a combination of manual, mechanical and automated sorting and recycling techniques, to process over 600,000 tonnes of municipal solid waste annually; and recovers fibres, ferrous and non-ferrous metals, plastics, and other materials which are used for a variety of applications.

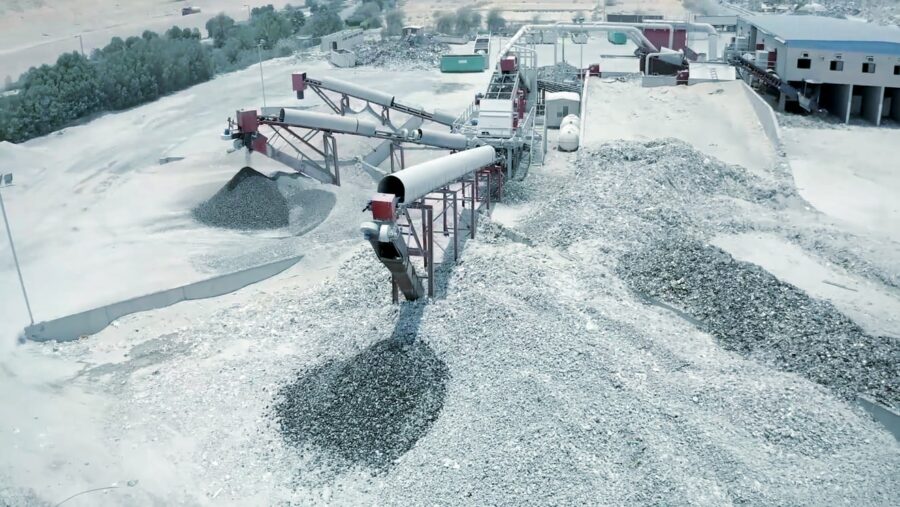

Construction and Demolition Waste Recycling Facility

(CDW)

The first of its kind in the MENA region, the Construction and Waste Demolition Facility has played a pivotal role in diverting the UAE’s substantial construction waste away from landfill. It treats and processes around 500,000 tonnes of heavily contaminated construction & demolition waste annually, turning it into industry-certified recyclable products such as curb stones, interlock, and recycled aggregate; which are further used as base or sub-base for roads and other construction applications.

Tyre Recycling Facility (TRF)

The Tyre Recycling Facility is a world-class facility that uses state-of-the-art cryogenic processes to recycle used tyres. The TRF is equipped to process up to 3 million tyres every year, and produces high-quality ISO certified crumb rubber, rubber mulch, rubber tiles and pavers, molded rubber products and rubberized asphalt. These products are used in flooring applications such as running tracks, grass-surfaced playing areas, stadium playing areas, miniature golf courses and in artificial turf infill.

Metal Recycling Center (MRC)

The Metal Recycling Center forms part of the company’s integrated waste management solution and houses the world’s most powerful shredding machine. The Center shreds old car bodies and other light metal scrap, and segregates the individual metal, glass and plastic components for recycling. These materials are further processed into very small pieces, which can be used by steel mills to manufacture new products.

Industrial Waste Water Treatment Plant (IWWTP)

Industrial Waste Water Treatment Plant treats 350m3 of industrial wastewater every day. Using physical, chemical and biological processes, the facility produces clean water, which is certified as safe for irrigation. The facility also ensures proper disposal of wastewater to prevent environmental contamination.

Biomass Facility

Launched in 2020, the Biomass Facility processes 200 tonnes waste daily, to generate alternative fuel. After segregating cellulous and carbon-based waste from construction, furniture, biological and bulky waste, the plant processes and converts these materials into wood chips, which act as a clean energy source for cement factories and paper mills. The facility reduces fossil fuel consumption, minimizes energy costs, and supports the transition to a circular economy.

Alternative Raw Material Facility (ARM)

Developed in partnership with Polyeco Group, a global environmental protection company, the world-class Alternative Raw Material Facility is the first dedicated marine waste treatment facility in the region. The facility uses advanced recycling techniques and equipment to treat and process maritime waste and marine-related hazardous waste. The ARM can produce up to 120 tonnes of alternative raw materials, which can be reintegrated into the economy.

Commercial & Industrial Facility (C&I)

The Commercial and Industrial (C&I) Facility is designed to process industrial waste with a 34% recovery rate. It is equipped with specialized AI and robotics systems to supplement recovery efforts at the MRF within BEEAH Recycling’s Waste Management complex. The C&I facility aims to further increase the landfill waste diversion rate, producing aluminium, HDPE, plastic car parts, wood, tyres, PET, PP containers and sacks, paper, carton, aluminium, and mixed film. It also produces light and oversized residue, which is then sent to the Solid Recovered Fuel (SRF) facility for further processing into an alternative green fuel.

Solid Recovered Fuel Facility (SRF)

The Solid Recovered Fuel Facility (SRF) is an alternative fuel facility that produces a low-emission and high-efficiency green fuel as an alternative to the coal being used in cement production. A first in the region, the facility produces up to 73,000 tons of high-quality alternative fuel while diverting 85,000 tons of waste away from landfill each year. The fuel produced by the facility is injected into kilns in cement factories, lowering their emissions, supporting net-zero targets and contributing to the circular economy.

To view the quality policy of BEEAH Recycling, please click here.

Landfills

BEEAH Recycling manages two of the largest engineered landfill cells for municipal solid waste in Sharjah. The first cell has a capacity of 3,100,000 million³ of waste over 10 years; while the second can accommodate 2,500,000 m³ of waste across a period of eight years. The company also has hazardous waste landfill cells, which have a capacity of 150,000m³ over 10 years. The MSW landfill cells are single-lined, while the hazardous are double-lined for greater protection. The linings include 2mm high-density polyethylene double-textured Geomembrane, Geosynthetic Clay Liners (GCL) and engineered layers (compacted sand) with leachate monitoring and collection systems.

Wekaya, BEEAH Group’s joint venture with Green Planet, is a premier medical waste management facility. It specializes in the safe collection, treatment and disposal of medical waste.

By using stringent control measures, accurate documentation and advanced systems, Wekaya ensures maximum infection control, establishing itself as the facility of choice for healthcare providers, throughout the region.

For more information on Wekaya, please visit this link.

BEEAH Recycling joined forces with leading Italian company, Ambienthesis, to establish B&A Waste Management, an end-to-end, integrated, industrial waste management company. B&A Waste Management covers design, construction and management of recycling plants; in addition to environmental management services; treatment, recovery and disposal of hazardous industrial waste; as well as soil and groundwater remediation activities. B&A Waste Management currently manages the operations and maintenance of a UAE-based, and two Italy-based, industrial wastewater facilities.

Evogreen is a joint venture between BEEAH Recycling and Greek-owned Polygreen, that offers innovative marine environmental management solutions. Launched in June 2021, Evogreen addresses a spectrum of maritime waste and pollution issues through oil spill response service; management of distressed vessels, cargo and abandoned containers including recycling or recovery solutions, repair or refurbishment works; green ship recycling and establishing an environmental laboratory.

Evogreen has already established an Alternative Raw Material facility in BEEAH’s Waste Management Complex in Sharjah. The facility is the first in the region to treat maritime waste and marine-related hazardous waste and generate alternative raw materials for industrial use.